Are you looking for a reliable partner for the production of your electronic equipment?

At Seven Elettronica we have been doing this for over 25 years, with efficiency, professionalism and a careful eye on sustainability.

Production Made in Seven

Are you looking for

a partner to produce your equipment electronic?

We at Seven Elettronica have been doing this for over 25 years, with efficiency, competence and now more than ever a focus on sustainability.

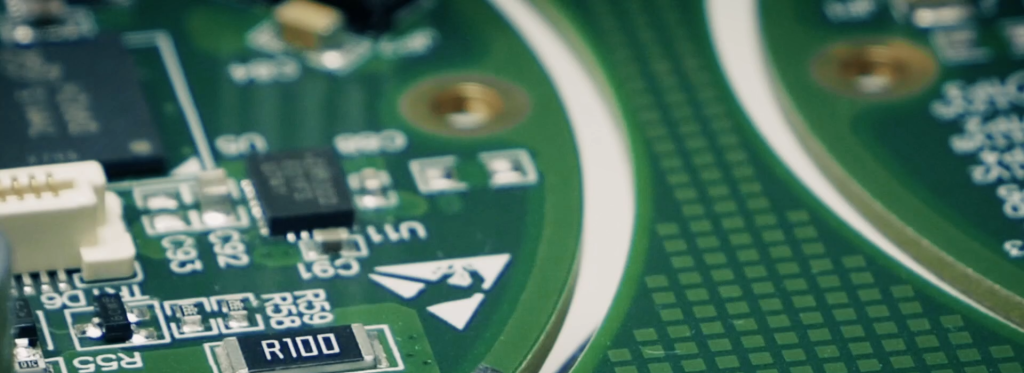

Electronic Manufacturing Services

Process Research & Development

Simplification of processes, both production and logistics, is for us synonymous with Quality, reduced lead times and lower costs.

Supply chain

A resilient and consolidated supply chain reduces risks and fluctuations and promotes production stability.

Production

The production cycle is distributed between San Giovanni in Persiceto (Italy) and Balatonboglár (Hungary) to guarantee product quality and optimise costs.

Post Production

After delivery of your electronic equipment, we can provide you with the solution for technical support and repair in a very short time.

COMPANY

We have been operating in the E.M.S. sector for over 25 years, combining technical expertise, innovation and a strategic vision to provide customised electronic manufacturing solutions.

With offices in Italy and Hungary, we ensure quality, traceability and an integrated approach that accompanies our customers at every stage of production.

ESG

Constant commitment to responsible practices, respecting international ISO standards and the ESG certifications.

Speed

Fast and flexible responses, with high standards of quality and safety in every product.

Vanguard

Constantly evolving processes for efficient and sustainable solutions through advanced technology and creativity.

Control

Every stage of production is monitored in real time thanks to Magda™, our Artificial Intelligence.

The industry we operate in? YOURS!

No matter the sector: from IoT to industrial automation, from biomedicine to renewable energy. If you need to assemble electronic boards, we are here for you. We don't limit ourselves to traditional industries: we work with anyone who brings innovative ideas to life!